- Scope

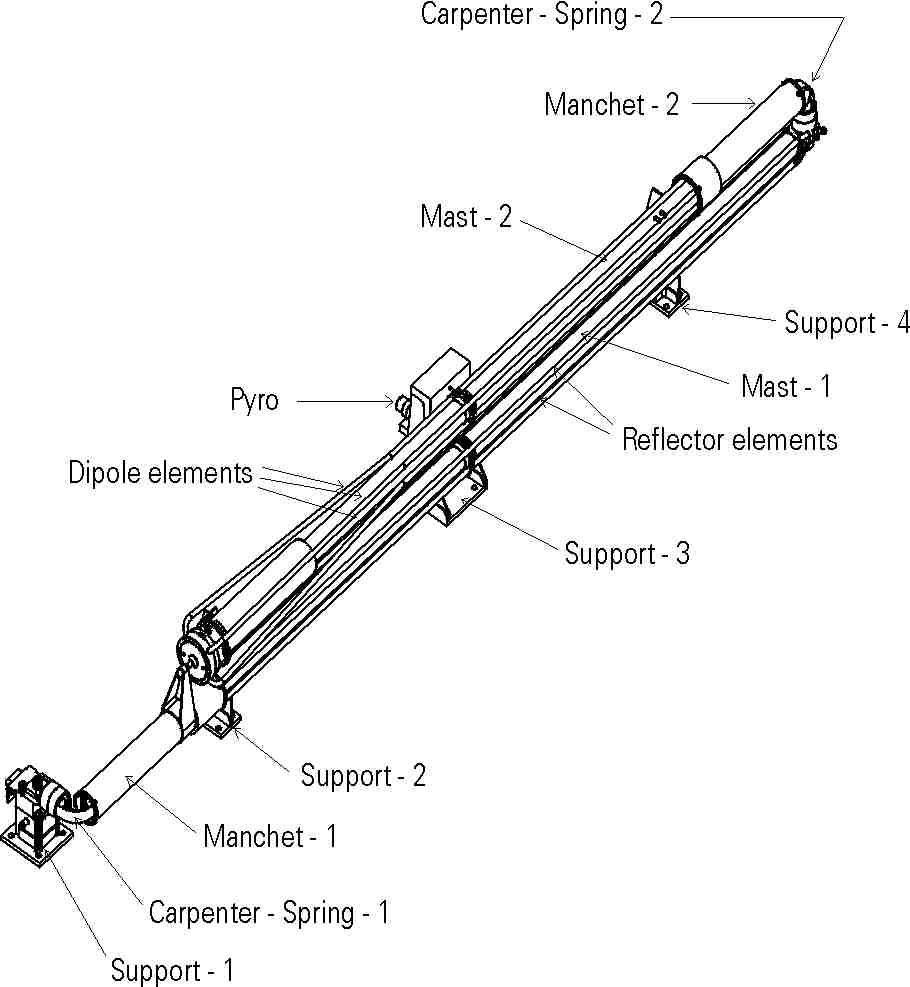

- Antenna Folded on Attachment Plate

- Applicable Documents

- Reference Documents

- Test Equipment

- Acronyms

This Testprocedure covers Project :

Consert-Antenna (STM) on Rosetta - S/C

Fig. 1 Antenna folded on Attachment plate

The purpose of this test is to determine the properties of the Consert-Antenna i.e. dimensions , reference point , interface pattern measurements , surface flatness of attachment plate, mass , centre of gravity , natural frequencies , electrical verification , etc..

|

no. |

document name |

document number |

Iss./Rev. |

|

AD1 |

Consert Orbiter Antenna MICD |

RO-OCN-DW-3001 |

2/E |

|

AD2 |

General Background on Handling of the Orbiter Antenna and on Terminology Consult |

RO-OCN-DW-3019 |

Version 1.3 |

|

AD3 |

|||

|

no. |

document name |

document number |

Iss./Rev. |

|

RD1 |

EIDA |

RO-EST-RS-3001 |

2/0 |

|

RD2 |

EIDB |

RO-EST-RS-3001 |

1/0 |

|

RD3 |

EIDC |

RO-EST-RS-3001 |

1/1 |

|

RD4 |

Space Engineering |

ECSS-E-10-03 / 5.1.16 |

Draft 01F |

|

RD5 |

Payload units STM build standard description |

TOS-MMS/1998/550/ln/JCS |

0 |

|

RD6 |

STM-test objective and built-standard definition |

RO-DSS-TN-1027 |

2 |

|

Nr. |

Instr. / Equipment Description |

Manufacturer |

Model/Type-Nr. |

Inv. Nr. |

Calibration Last Next |

|

1 |

Digital Caliper Rule |

Minimax |

K/03 20118 |

94096 |

|

|

2 |

Knife Edge Straight-Edge |

Hauser |

|||

|

3 |

Thickness Gauge |

Orion/Germany |

DIN 2275 |

||

|

4 |

Balance |

Sartorius |

86070100 |

||

|

5 |

Centre Microscope |

Hensold |

65576 |

||

|

6 |

X/Y/Z-Digital Table |

Heidenhain |

PT855 |

||

|

7 |

Multimeter |

Keithly |

90011200 |

||

|

8 |

Low-Resistance Measurement |

Keithly |

195 |

MPAe Max-Planck-Institut für Aeronomie

STM Structural and Thermal Model

AD Applicable Document

RD Reference Document

FM Flight Model

Hz Hertz

Q-Level Qualification Level

M Mass

mm millimeter

g Acceleration

wrt. with respect to

I/F Interface

URF Unit Reference Frame

The Structural and Thermal Model (STM) of the Consert Antenna is mass and thermal representative of the Consert Antenna (FM). The size of the Antenna is 1135 mm x 100 mm x 125 mm. The Antenna weight is 1.45 kg.

Cleanliness: 100 000

Temperature: 20 ° C

Humidity: < 50 %

- Visual Inspection

- General Appearance

- Thermal Finish

- Connectors

- Connector Savers< /FONT>

- Protective Covers

- Test Covers<

/TD>

None

- Harness

- Cleanliness

- Safety Devices

- Safety Caps on Connectors JA2 / JA3

- Safety Strings and Red Tags on

- I/F Measurements

- Support 1

- Mounting Hole

- Hole Diameter

- Spot Face Diameter

- Mounting Feet

- Mounting Feet Thickness

- Mounting Feet Contact

- Isolation Bushes

- Surface Flatness

- Support 2

- Mounting Hole

- Hole Diameter

- Spot Face Diameter

- Mounting Feet

- Mounting Feet Thickness

- Mounting Feet Contact

- Isolation Bushes

- Surface Flatness

- Support 3

- Mounting Hole

- Hole Diameter

- Spot Face Diameter

- Mounting Feet

- Mounting Feet Thickness

- Mounting Feet Contact

- Isolation Bushes

- Surface Flatness

- Support 4

- Mounting Hole

- Hole Diameter

- Spot Face Diameter

- Mounting Feet

- Mounting Feet Thickness

- Mounting Feet Contact

- Isolation Bushes

- Surface Flatness

- Physical Properties

- CoG / MoI

- Natural Frequencies

- Electrical Verifications

- Deployment Indicators

- Grounding

- Connector Locations ( JA4 / JA1 / JA2 / JA3

- Safety Harness : Strings and Red Tag Items

|

|

OK |

|

|

|

Plasmocer Black and White Iridite ; PUI Black Paint

|

|

|

|

OK |

|

|

|

N/A for STM |

|

|

|

None |

|

|

| ||

|

|

See Material List |

|

|

|

Visible Clean |

|

|

|

for Pyro-Connection Supports 2 and 4

|

|

|

To be handled by hand with gloves in class 100000 clean room |

|

Step |

Specification |

Actual |

Remarks |

|||

|

L W H |

1135 mm 100 mm 125 mm |

|||||

|

|

(Holes -Nr. Clockwise from upside) |

|||||

|

Position URF

Tol.: ± 0,1 mm |

1 2 3 4(R) |

Xu Yu0 36 36 36 36 0 0 0

|

Xu Yu-0,14 36,13 35,98 36,01 36,12 0,16 0 0

|

|||

|

|

1 2 3 4 |

4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm |

4,24 4,24 4,23 4,23 |

|||

|

|

1 2 3 4 |

N/A |

||||

|

Dimensions |

1 2 3 4 |

|

||||

|

|

1 2 3 4 |

4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm |

4,06 4,04 4,06 4,05 |

|||

|

Area |

1 2 3 4 |

|

||||

|

|

None |

|||||

|

|

100 m |

|||||

|

Step |

Specification |

Actual |

Remarks |

||

|

|

(Holes -Nr. Clockwise from upside) |

||||

|

Position URF

Tol.: ± 0,1 mm |

1 2 3 4(r) |

Xu Yu 0 41 20 41 20 0 233 -33 |

Xu Yu -0,10 40,99 19,93 40,95 19,99 -0,05 0 0 |

1 – 3 refer to 4(r) 4(r) refer to 4(R) at support 1 |

|

|

|

1 2 3 4 |

4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm |

4,23 4,22 4,23 4,22 |

||

|

|

1 2 3 4 |

N/A |

|||

|

Dimensions |

1 2 3 4 |

|

|||

|

|

1 2 3 4 |

4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm |

4,04 4,03 4,06 4,04 |

||

|

Area |

1 2 3 4 |

|

|||

|

|

None |

||||

|

|

100 m |

||||

|

Step |

Specification |

Actual |

Remarks |

||

|

|

(Holes-Nr. Clockwise from upside) |

||||

|

Position URF

Tol.: ± 0,1 mm |

1 2 3 4(r) |

Xu Yu 0 41 40 41 40 0 578 -33 |

Xu Yu-0,01 41,03 39,98 41,12 40,01 0,07 0 0 |

1 – 3 refer to 4(r) 4(r) refer to 4(R) at support 1 |

|

|

|

1 2 3 4 |

4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm |

4,22 4,23 4,23 4,22 |

||

|

|

1 2 3 4 |

N/A |

|||

|

Dimensions |

1 2 3 4 |

|

|||

|

|

1 2 3 4 |

4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm |

4,05 4,07 4,04 4,07 |

||

|

Area |

1 2 3 4 |

|

|||

|

|

None |

||||

|

|

100 m |

||||

|

Step |

Specification |

Actual |

Remarks |

||

|

|

(Holes -Nr. Clockwise from upside) |

||||

|

Position URF

Tol.: ± 0,1 mm |

1 2 3 4(r) |

Xu Yu0 41 20 41 20 0 908 -33 |

Xu Yu0,06 40,97 19,90 40,98 20,01 0,05 0 0 |

1 – 3 refer to 4(r) 4(r) refer to 4(R) at support 1 |

|

|

|

1 2 3 4 |

4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm 4,3 -0/+0,1 mm |

4,25 4,24 4,24 4,24 |

||

|

|

1 2 3 4 |

N/A |

|||

|

Dimensions |

1 2 3 4 |

|

|||

|

|

1 2 3 4 |

4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm 4 0/0,1 mm |

4,05 4,06 4,08 4,05 |

||

|

Area |

1 2 3 4 |

|

|||

|

|

None |

||||

|

|

100 m |

||||

Mass Properties

|

See RO-OCN-DW-3001 |

STM Mass Breakdown (grams) (actuel) |

FM Mass predicted |

Remarks |

|

1447 |

1450 ± 10 |

With Cabling |

|

STM Measured |

FM Predicted |

Diff. In % |

|

|

Total Mass M |

|||

|

CoG X Y Z |

|

502 mm. -22 mm. 63 mm. |

|

|

MoI Ixx (wrt. CoG) Iyy Izz |

1.6 x 10-3 Kgm2 1.6 x 10-1 Kgm2 1.6 x 10-1 Kgm2 |

See Vibration report RO-OCN-TR-3021

|

STM |

Predicted for FM |

|

|

1st Natural Frequency X-Axis |

320 |

|

|

1st Natural Frequency Y-Axis |

145 |

|

|

1st Natural Frequency Z-Axis |

150 |

Each Carpenter-Spring is supplied with an Resistor(R) to provide a deployment-check.

See connector Location 4.4.3

|

Folded Antenna |

Deployed Antenna (to be measured after Deployment-Test) |

||||

|

Connector JA4 |

Specification

|

Actual Value |

Specification |

Actual Value |

|

|

Carpenter Spring 1 |

P 7 P 2 |

R < 50 W |

0.4 |

R > 1 MW |

> 1 MW |

|

Carpenter Spring 2 |

P9 P4 |

R < 50 W |

0.4 |

R > 1 MW |

> 1 MW |

|

Description |

Specification |

Actual |

|

Dipoles / Mast-2 |

£ 25 mW |

|

|

Mast-2 / Manchet-2 |

£ 25 mW |

|

|

Mast-2 / Mast-1 |

£ 25 mW |

|

|

Mast-1 / Manchet-1 |

£ 25 mW |

|

|

Mast-1 / Support-1 |

£ 25 mW |

|

|

Support-1 / Spacecraft |

£ 10 mW |

|

|

Support-2 / Spacecraft |

£ 10 mW |

|

|

Support-3 / Spacecraft |

£ 10 mW |

|

|

Support-4 / Spacecraft |

£ 10 mW |

|

|

Ground Stud /Spacecraft |

£ 2.5 mW |

|

|

Surfaces / ... |

< 1 kW |

> 1 kW |

Fig. 4 Connector Location on Support - 1

JA4

JA4

JA1

Fig. 5 Connectors JA2 / JA3 on Pyro with Safety Caps on Support 3

Fig. 6 Safety Strings and Red Tag Items

- Non-Conformance (NCR)

- Procedure Sign Off Sheet

- Signatures

- Attachments

Where any out of limits results is obtained during the test , the result shall be annotated clearly as being a test failure and the Non-Conformance-Reporting according to EID A

Issue 1 , Rev. 0 Sec.: 3.3.8 and Section 8.33.1 will be initiated.

A NCR Consert-Formsheet RO-OCN-MPAE-FO-007.doc is attached.

A summery of all out of limits results (NCR-Overview) should be appended to the test report.

A NCR-Overview Consert-Formsheet RO-OCN-MPAE-FO-007_ov.doc is attached.

The identified test item has been successfully tested in accordance with the foregoing procedure and all open items (e.g. NCR's) are closed except those listed below:

|

No. |

Doc.Nr. |

Title |

Version |

Date |

Remarks |

|

1 |

RO-OCN-DW-3001 |

MICD |

2/D |

Item # 6 |

|

Identification Labels

Identification Labels

Table 5

Grounding Values

Table 5

Grounding Values