CONSERT - Antenna

on Rosetta S/C

Project Deployment Test Report

of the

Consert S/C-Antenna STM

after Centrifige Test

RO-OCN-TR-3003.4

Issue: 1

Revision: -

01.08.1999

Prepared by:

W. Engelhardt and E.Nielsen / W.Boogaerts

Approval Sheet

prepared by: E.Nielsen / W.Boogaerts (signature/date)

approved by technical department: W.Engelhardt (signature/date)

approved by Consert-Management: Dr. E.Nielsen (signature/date)

approved by QA/PA : W.Boogaerts (signature/ date)

Document Change Record

|

Iss./Rev. |

Date |

Pages affected |

Description |

|

1/- |

01.08.1999 |

All |

Deployment after Centrifuge Test |

Distribution Record

|

Holder |

Issue/Revision |

||||||||||||||||

|

Draft |

1/- |

1a |

2 |

||||||||||||||

|

Consert-Documentation MPAE |

C |

||||||||||||||||

|

WB |

W.Boogaerts |

A/C |

|||||||||||||||

|

LB |

L.Bemman |

C |

|||||||||||||||

|

EN |

Dr. Nielsen |

A/C |

|||||||||||||||

|

Prof. Hagfors |

|||||||||||||||||

|

HP |

H.Perplies |

A/C |

|||||||||||||||

|

KG |

K.Gräbig |

||||||||||||||||

|

WE |

W.Engelhardt |

A/C |

|||||||||||||||

|

ESA |

G. Gianfiglio |

C |

|||||||||||||||

|

J-P. Goutail |

A/C |

||||||||||||||||

|

Legend: A - Approval |

|||||||||||||||||

Table of contents

1.0 General aspects *

1.1 Scope *

1.2 Introduction *

1.3 Applicable Documents *

1.4 Reference Documents *

1.5 Acronyms *

2.0 Equipment under Test *

3.0 Test Conditions *

4.0 Ground Support Equipment (MGSE) *

5.0 Test Steps *

5.1 Preparations *

5.2 Deployment *

6.0 Non-Conformance (NCR) *

7.0 Procedure Sign Off Sheet *

8.0 Signatures *

9.0 Attachments *

List of Figures

Fig. 1 Antenna folded on Attachement Plate *

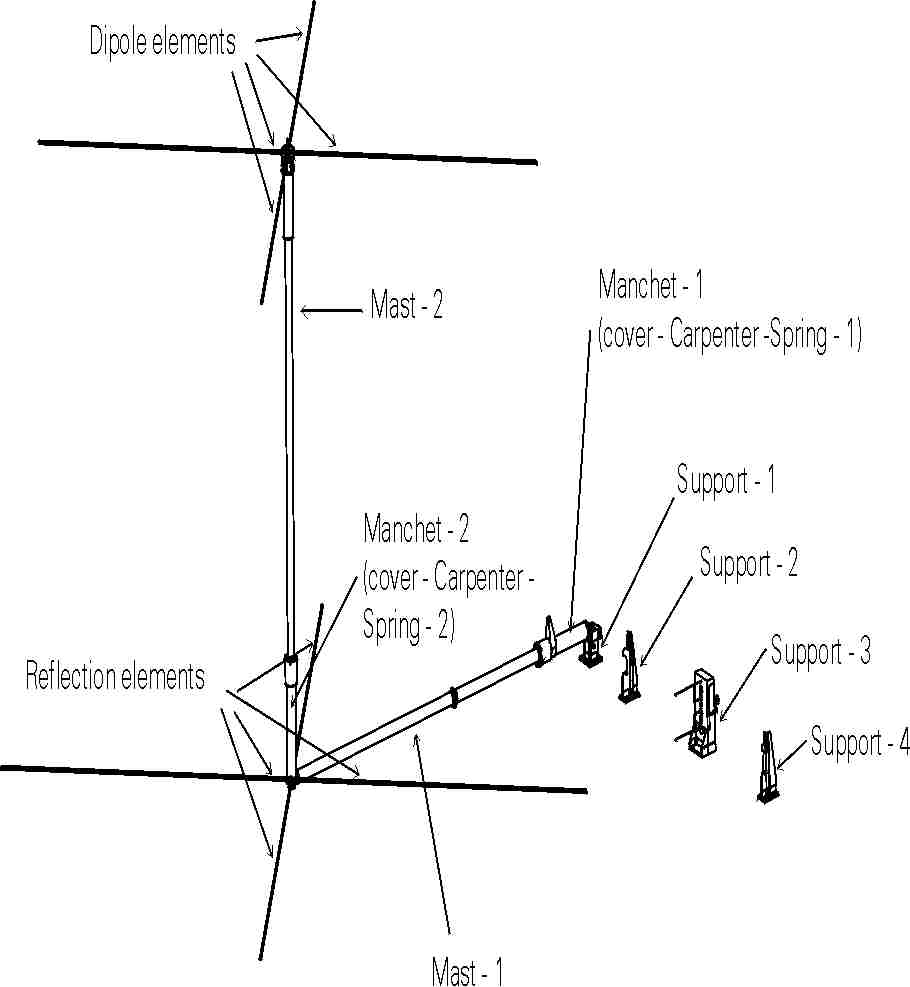

Fig. 2 The folded antenna with the major parts named

*Fig. 3 Antenna deployed

*

List of Tables

Table 1 Tests Overview *

Table 2: Applicable Documents

*Table 3: Reference Documents

*Table 4 Ground Support Equipment

*Table 5: Open Items

*Table 6 Signatures

*Table 7 Attachments

*

General aspects

This Testprocedure covers Project :

Consert-Antenna (STM)

Fig. 1 Antenna folded on Attachement Plate

The test carried out according to this procedure shall demonstrate the deployment functionality of the Consert-Antenna after the following test :

|

Test |

Doc. Nr. |

Description |

Remarks |

|

Centrifuge Test |

RO-OCN-TR-3005 |

Centrifuge Test |

A correct deployment means that the deployment indicators show the correct signal prior to deployment (signaling a stowed antenna), that the antenna deployment takes place in an orderly and defined sequence, that the locking mechanisms are latching-on at the end of the deployment, and that the electrical deployment indicators are showing the correct signal at the end of the deployment (signaling a deployed antenna).

For general background on handling of the orbiter antenna and on terminology consult RO-OCN-TN-3019, version 1.2.

Correct deployment is defined as:

1) There are two deployment indicators; one on each Carpenter-Spring. The indicators are connected to connector JA4 on Support 1.

The deployment indicator on Carpenter-Spring-1 is connected to Pins 2 and 7.< /P>

The deployment indicator on Carpenter-Spring-2 is connected to Pins 4 and 9.< /P>

For stowed antenna: Deployment indicator value is an Ohmic resistance of < 50 Ohm.

For deployed antenna: Deployment indicator value is an Ohmic resistance of > 1MOhm.

2) The sequence of deployment is:

The test will be performed with MPAE - Equipment by MPAe personnel.

The test progress will be documented by pictures and Video Recording.

Applicable Documents

|

No. |

Document Name |

Document Number |

Iss./Rev. |

|

AD1 |

Consert Orbiter Antenna Mechanical I/F |

RO-OCN-DW-3001 Pages 1-3 |

2/E

|

|

AD2 |

general background on handling of the orbiter antenna and on terminology consult |

RO-OCN-TN-3019 |

Version 1.3 |

|

No. |

Document Name |

Document Number |

Iss./Rev. |

|

RD1 |

EIDA |

RO-EST-RS-3001

|

1/1 |

|

RD2 |

EIDB |

RO-EST-RS-3001 |

1/0 |

|

RD3 |

EIDC |

RO-EST-RS-3001 |

|

MPAe Max-Planck-Institut für Aeronomie

STM Structural and Thermal Model

AD Applicable Documents

RD Reference Documents

FM Flight Model

The Structural and Thermal Model (STM) of the Consert Antenna is mass and thermal representative of the Consert Antenna (FM). The size of the Antenna is 1128 mm x 100 mm x 125 mm. The Antenna weight is 1.45 kg.

Cleanliness: 100 000

Temperature: 20 ° C

Humidity: < 50 %

4.0 Ground Support Equipment (MGSE)

Table 4 Ground Support Equipment

|

Nr. |

Instr. / Equipment Description |

Manufacturer |

Identification-Nr. |

Model/Type-Nr. |

Inv. Nr. |

Remarks |

|

1 |

Deployment Bracket |

MPAE |

OCN-MGSE-01 |

See AD2 |

||

|

2 |

Holding Bracket A |

MPAE |

OCN-MGSE-02 |

|||

|

3 |

Holding Bracket B |

MPAE |

OCN-MGSE-03 |

|||

|

4 |

Balloons |

OCN-MGSE-04 |

||||

|

5 |

Counter Weight |

MPAE |

OCN-MGSE-05 |

|||

|

6 |

String Attachement |

MPAE |

OCN-MGSE-06 |

|||

|

7 |

Multimeter |

OCN-MGSE-07 |

||||

|

8 |

4 Pieces of String, about 4 m. each |

MPAE |

OCN-MGSE-08 |

|||

|

9 |

Helium Bottle Attachement |

MPAE |

OCN-MGSE-09 |

|||

|

10 |

Wire-Cutter |

MPAE |

OCN-MGSE-10 |

|||

|

11 |

Bottle with Helium |

Provided by Integrator |

||||

Fig. 2 The folded antenna with the major parts named

Location : ________________________________________________ _________________

|

Step |

Picture-Nr. / Video |

Activity |

Executed by [Initials] |

OK Y/N |

Comments |

|

10 |

Place Antenna Horizontally > 1m over Ground |

||||

|

20 |

Assemble and prepare the ‘Deployment Bracket’ |

||||

|

30 |

Attach ‘Deployment Bracket’ to the crane hook |

||||

|

40 |

Position crane hook over Support-1 |

||||

|

50 |

Attach the string through the ‘Deployment Bracket’ to Support-1 |

||||

|

60 |

Position crane hook exactly to make sure that the vertical part of the ‘Deployment Bracket’ is vertical |

||||

|

70 |

Mount the ‘String Attachment’ and connect the ‘Deployment Bracket’ |

||||

|

80 |

Fill balloon(s) with helium so that they balance the ‘Counter Weight’ |

||||

|

90 |

Fasten the balloon(s) to the top of Mast-2 |

||||

|

Step |

Picture-Nr. / Video |

Activity |

Executed by [Initials] |

OK Y/N |

Comments |

|

100 |

Remove Pyro :

|

||||

|

110 |

Antenna is ready to be deployed? |

|

Step |

Picture-Nr. / Video |

Activity |

Executed by [Initials] |

OK Y/N |

Comments |

|

|

200 |

Check Deployment Indicators: JA4: R < 50W Carpenter Spring 1 (JA4, PIN 2,7) Carpenter Spring 2 (JA4, PIN 4,9) |

|||||

|

210 |

Cut the Pyro Wire with the Wire-Cutter at the point where the Pyro would have cut |

|||||

|

220 |

Watch deployment sequence as the Antenna deploys :

|

|||||

|

Step |

Picture-Nr. / Video |

Activity |

Executed by [Initials] |

OK Y/N |

Comments |

|

|

230 |

Verify that Manchets are locked on :

|

|||||

|

240 |

Check the Deployment-Indicators : (on JA4 . R > 1 MW )

(JA4, PIN 2,7)

(JA4, PIN 4,9) |

|||||

Where any out of limits results is obtained during the test , the result shall be annotated clearly as being a test failure and the Non-Conformance-Reporting according to EID A

Issue 1 , Rev. 0 Sec.: 3.3.8 and Section 8.33.1 will be initiated.

A NCR Formsheet RO-OCN-MPAE-FO-007.doc is attached.

A summery of all out of limits results (NCR-Overview) should be appended to the test report.

A NCR-Overview Formsheet RO-OCN-MPAE-FO-007_ov.doc is attached.

Procedure Sign Off Sheet

The identified test item has been successfully tested in accordance with the foregoing procedure and all open items (e.g. NCR's) are closed except those listed below:

Signatures

Attachments

|

No. |

Doc.Nr. |

Title |

Version |

Date |

Remarks |

|

1 |

RO-OCN-MPAE-NCR-002 |

||||